OEM/ODM Manufacturer Precision Steel Tube - Precision stainless steel strip – Zheyi

OEM/ODM Manufacturer Precision Steel Tube - Precision stainless steel strip – Zheyi Detail:

Description

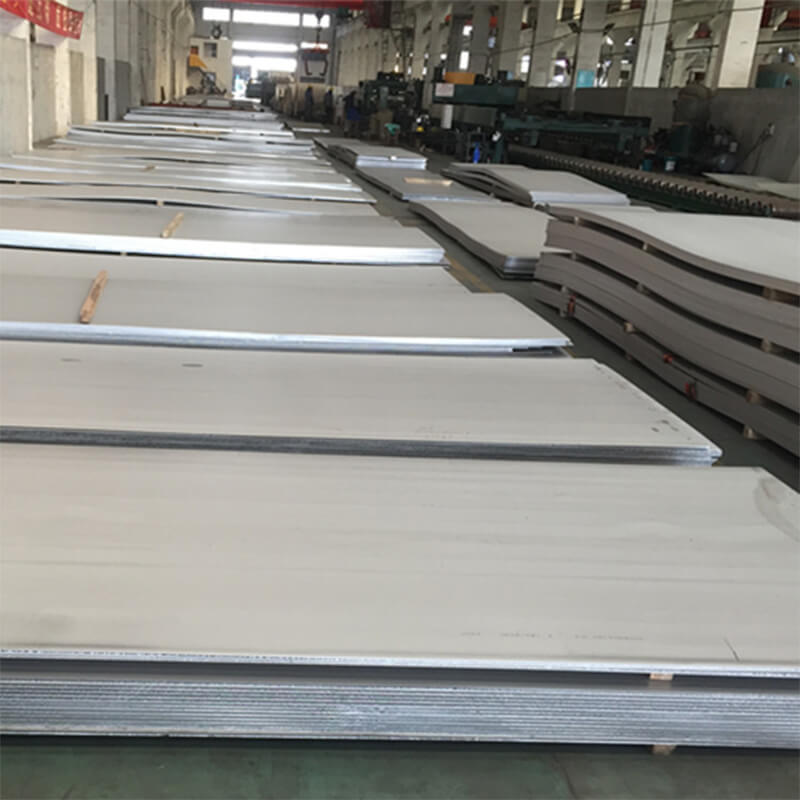

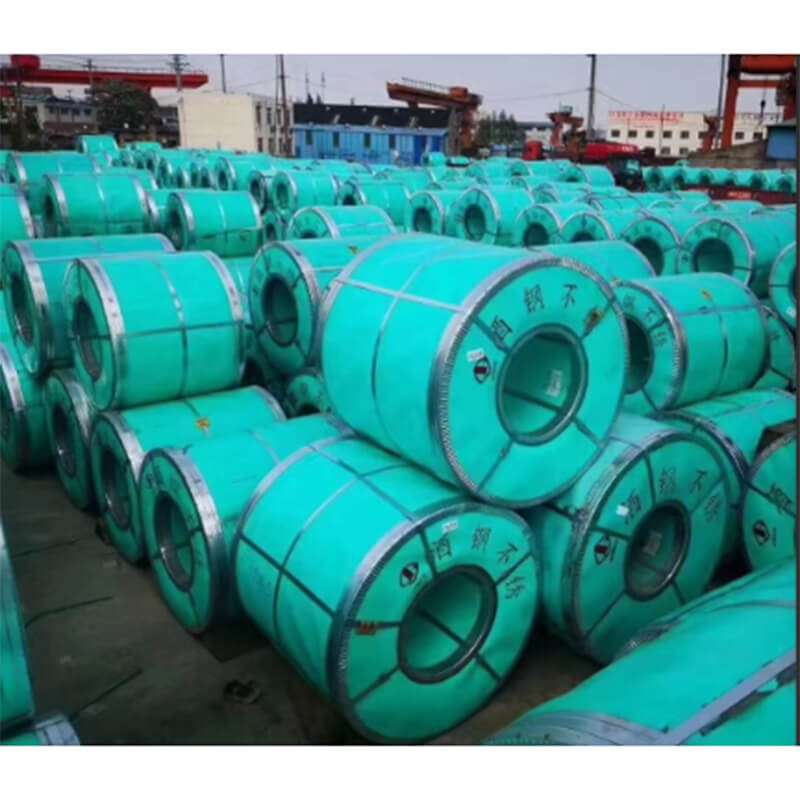

Precision stainless steel strip is a type of plate, which is actually a thin steel plate that is long and narrow and supplied in coils. The main difference between Coiled plate and flat sheets lies in cutting and packaging.

Coil is divided into chilled coil plate and cold rolled coil plate.

Chilled Coil are obtained by pickling and cold rolling of hot-rolled coils plate. It is a cold rolled coil plate. Cold-rolled coil plate (annealed): It can be obtained from hot-rolled coils plate through pickling, cold rolling, bell annealing, flattening, (finishing) processing.

There are three main differences between the two: Generally the default delivery state of cold rolled coil plate is annealed state.

1. In appearance, the color of chilled coils plate is generally micro black color.

2. In terms of surface quality, structure, and dimensional accuracy, cold-rolled coil plate are better than chilled coils plate.

3. In terms of performance, because the chilled coils plate directly obtained from the hot-rolled coils plate through the cold rolling process undergo work hardening during cold rolling, the yield strength is increased, and some internal stresses remain, and the external performance is relatively “hard”. Called chilled coil plate. And cold-rolled coil plate (annealed): It is obtained from the chilled coil plate through bell annealing before coiling. After annealing, the work hardening phenomenon and internal stress are eliminated (greatly reduced), that is, the yield strength decreases close to the cold Before rolling. Due to the yield strength, chilled coils are larger than cold-rolled coils plate (annealed), making cold-rolled coils plate (annealed) more conducive to stamping and forming.

Characteristics

Generally the default delivery state of cold rolled coil plate is annealed state.

Precision stainless steel strip coils. Enterprises in the purchase of coil after the uncoiling process can be processed, generally used in the automobile industry more.

Be it resistance to corrosion, acids, or heat: Our precision steel strip made of stainless steels offers maximum performance. Especially when increased demands are placed on formability or later properties. Our precision steel strip has proven its worth for many years, especially for demanding applications in medical technology, safety-relevant components in the automotive industry, and electrical engineering. In addition, stainless steel strip with extremely low nominal thicknesses is also used in the production of fuel cells. Especially when high requirements are placed on the formability and usage properties.

The main alloys chrome and nickel, in combination with molybdenum, niobium or titanium additives enable the high-precision calibration of further technological properties in addition to corrosion resistance such as deep drawability, bendability, or punchability as well as tailored spring propPrecision stainless steel strip is a cold rolled strip made from high quality stainless steel coil.

The most common grades are 201, 301, 304 and 316L. The strip may be uncoated or coated with a surface finish that enhances its corrosion resistance properties. It is available in thicknesses from 0.02mm to 3.0mm.

Precision stainless steel strip has excellent mechanical properties at room temperature and can be readily fabricated into parts by machining processes such as turning and drilling. It is also weldable by conventional methods, although welding must be done carefully because of the low melting point of the material.

Precision stainless steel strip is used by manufacturers in industries such as aerospace, automotive, marine, oil and gas, petrochemical, food processing and medical equipment.

Precision stainless steel strip can be manufactured in different grades depending on the desired characteristics of the final product. For example, grade 304 precision stainless steel strip is more resistant to corrosion than grade 321 precision stainless steel strip but both types are still suitable for use in marine environments since they will not rust or corrode over time.

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for OEM/ODM Manufacturer Precision Steel Tube - Precision stainless steel strip – Zheyi , The product will supply to all over the world, such as: Johannesburg, Switzerland, Guatemala, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.