Competitive Price for Composite Coiled Tubing - 1/4 Stainless Steel Tubing Coil – Zheyi

Competitive Price for Composite Coiled Tubing - 1/4 Stainless Steel Tubing Coil – Zheyi Detail:

Description

Stainless steel tubing coil is designed in coiling form, general small diameter, maximum tube length can be 1000 meters, without any joint metal, there are a large range sizes of stainless steel tubing for coiling, standard outside diameter is given below, and wall thickness ranges from 0.0275 inch – 0.083 inch, maximum length reach to 1000 meters.

Advantages Of Coil Tubing

The traditional method of welding long stick tubing end to end or with fittings, it is a very labor intensive procedure., this welding process is very slow and costly, using coil tubing not only takes a fraction of the time, reducing labor costs, it also provides for a much safer and maintenance free installation.

1/4 stainless steel tubing coilis used for wide range of applications, applied for cooling and heating transferring energy in corrosive and non normal temperature environment, like food and beverage, oil and gas, medicine industry and so on, we manufacture and design coiled tubing to meet customer requirement in different sharps and purpose.

Industrial stainless steel tubing coil applied for heat exchangers, boilers, oil, chemicals, fertilizers, chemical fiber, pharmaceutical, nuclear power and so on.

Fluid stainless steel coil tube applied for beverages, beer, milk, water supply systems and medical equipment.

Mechanical structure with stainless steel coil tube applied for printing and dyeing, printing, textile machinery, medical equipment, kitchen equipment, automotive and marine accessories, construction and decoration.

16/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)

Parameters

16/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)

|

Cr |

Ni |

C |

Mo |

Mn |

Si |

Ph |

S |

|

16.0-18.0 |

10.0-14.0 |

0.030 |

2.0-3.0 |

2.00 |

1.00 |

0.045 |

0.30* |

Nickel Alloy 825, 625 Coil Tubing

|

Grade |

UNS |

C(Max.) |

Cr |

Ni |

Mo |

Others |

|

Alloy 825 |

N08825 |

0.03 |

20 |

38.5 |

2.6 |

Cu=1.7, Ti=0.7 |

|

Alloy 625 |

N6625 |

0.1 |

21.5 |

>=58 |

9 |

Nb=3.5 |

After annealing, straighten stainless steel tubing is in soft condition, tubing can be bent, formed and fabricated in various directions and angles, small diameter and thin.

Working With SS Tubing Coil

The best advice to give anyone who works with steel brake line tubing is to use quality flaring tools. While steel brake lines are typically challenging, this is only true when flaring this sturdy material with cheap tools.

Even though stainless-steel brake tubing is more challenging to bend than other steel materials, it is still reasonably easy to shape. But this statement is only valid if you invest in top-notch flaring equipment.

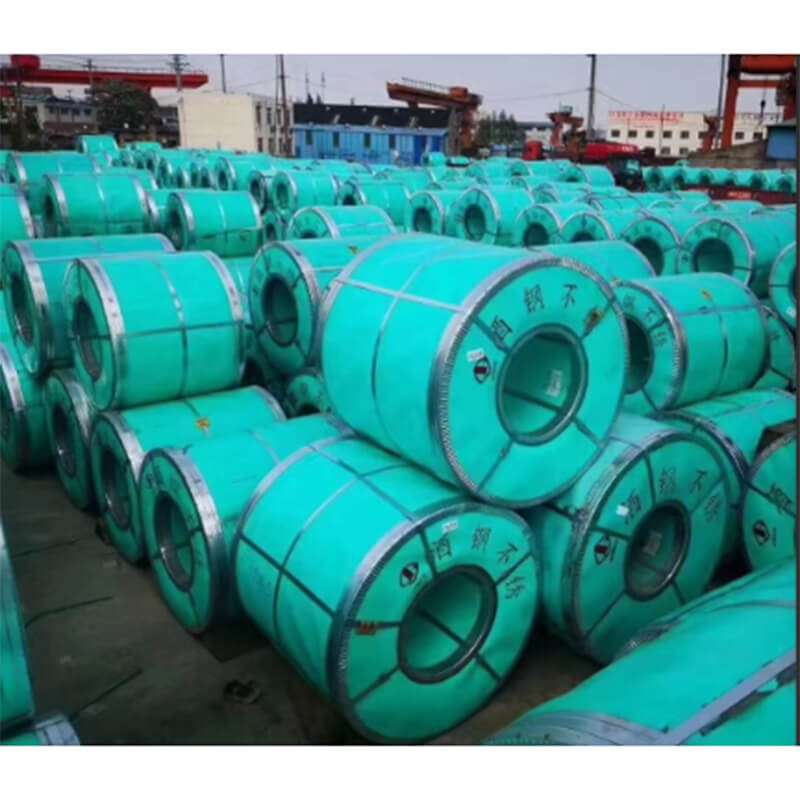

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Competitive Price for Composite Coiled Tubing - 1/4 Stainless Steel Tubing Coil – Zheyi , The product will supply to all over the world, such as: India, Russia, belarus, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!