19mm Round Mild Steel Tube And Pipe

stainless steel pipe

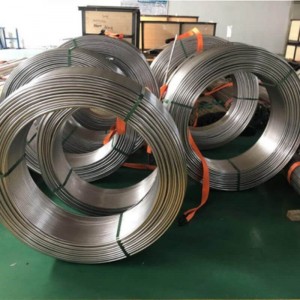

Seamless Stainless Steel Coil Pipe is an affordable stainless steel alloy that has most of the properties you would expect from stainless steel. You can solder it with no trouble as it is very malleable. However, it is also strong, durable, and corrosion-resistant. This type of stainless steel is not as resistant to salt water as other stainless steels, so it is not usually used in marine applications or other situations where there may be contact with salt water. However, it is very popular in applications such as machine parts due to its economy, machinability, and resistance.

Seamless Stainless Steel Coil Pipe is a stainless steel that contains molybdenum to increase its corrosion resistance to a level suitable for marine applications. Therefore, it is often referred to as marine-grade stainless steel. It can be used on ships, offshore rigs, surgical equipment, and other areas that may be exposed to salt water or other severely corrosive environments.

In the end, you need to decide whether you need a seamless rod or coil or welded rod or coil. You make welded pipe by welding metal strips into a tube shape, while you make seamless pipe by extruding steel from a metal rod and pulling it through a tubular die.

While welded pipes tend to be more economical, they are also less resistant to corrosion. In addition, seamless pipes have a 20% increase in working pressure compared to welded pipes of the same size and material.

Stainless Steel and Nickel Alloy Coils

Dongsheng Stainless Steel is a leading manufacturer of Seamless Stainless Steel Coil Pipe. Its products cover different grades of stainless steel, duplex steel, and nickel alloys, and materials are selected according to specific applications.

304/304L and 316/316L have widely used grades in the stainless steel group, with excellent corrosion resistance and performance. These stainless steels can withstand high temperature, low temperature, and high pressure, and are relatively cost-effective materials.

304/304L stainless steel coil

304 grade is a typical 18/8 Cr/Ni stainless steel material, which has good corrosion resistance and performance for many applications and is an economical grade, 304L is a low carbon 304 grade.

316 stainless steel is the second grade used and it contains 2.0 – 3.0 molybdenum which gives it better corrosion resistance than 304, so it is a good choice for marine applications.

Standard Stainless Steel Coil Sizes

Stainless steel pipes are designed in the form of coils, generally small diameter, the maximum pipe length can be up to 1000 meters, without any joint metal, coiled stainless steel pipes have a wide range of sizes, and the standard outside diameter is as follows, the wall thickness ranges from 0.0275 inches – 0.083 inches, the maximum length Up to 1000 meters.

Mechanical Properties and composition

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

||

|

304 |

min. max. |

- 0.08 |

- 2.0 |

- 0.75 |

- 0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 10.5 |

- 0.10 |

|

|

304L |

min. max. |

- 0.030 |

- 2.0 |

- 0.75 |

- 0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 12.0 |

- 0.10 |

|

|

304H |

min. max. |

0.04 0.10 |

- 2.0 |

- 0.75 |

-0.045 |

- 0.030 |

18.0 20.0 |

- |

8.0 10.5 |

- |

|

|

Grade |

Tensile Strength (MPa) min |

Yield Strength 0.2% Proof (MPa) min |

Elongation (% in 50mm) min |

Hardness |

|

|

Rockwell B (HR B) max |

Brinell (HB) max |

||||

|

304 |

515 |

205 |

40 |

92 |

201 |

|

304L |

485 |

170 |

40 |

92 |

201 |

|

304H |

515 |

205 |

40 |

92 |

201 |

|

304H also has a requirement for a grain size of ASTM No 7 or coarser. |

|||||

▼Stainless steel coiled tubes/coil tubing common size range

|

Size of Stainless steel Coil Tube |

|

Size of Stainless steel Coil Tube |

||||

|

ITEM |

Grade |

Size |

Pressure |

Length |

|

1 |

316L、304L、304 alloy 625 825 2205 2507 |

1/8″×0.025″ |

3200 |

500-2000 |

|

2 |

316L、304L、304 alloy 625 825 2205 2507 |

1/8″×0.035″ |

3200 |

500-2000 |

|

3 |

316L、304L、304 alloy 625 825 2205 2507 |

1/4″×0.035″ |

2000 |

500-2000 |

|

4 |

316L、304L、304 alloy 625 825 2205 2507 |

1/4″×0.049″ |

2000 |

500-2000 |

|

5 |

316L、304L、304 alloy 625 825 2205 2507 |

3/8″×0.035″ |

1500 |

500-2000 |

|

6 |

316L、304L、304 alloy 625 825 2205 2507 |

3/8″×0.049″ |

1500 |

500-2000 |

|

7 |

316L、304L、304 alloy 625 825 2205 2507 |

1/2″×0.049″ |

1000 |

500-2000 |

|

8 |

316L、304L、304 alloy 625 825 2205 2507 |

1/2″×0.065″ |

1000 |

500-2000 |

|

9 |

316L、304L、304 alloy 625 825 2205 2507 |

φ3mm×0.7mm |

3200 |

500-2000 |

|

10 |

316L、304L、304 alloy 625 825 2205 2507 |

φ3mm×0.9mm |

3200 |

500-2000 |

|

11 |

316L、304L、304 alloy 625 825 2205 2507 |

φ4mm×0.9mm |

3000 |

500-2000 |

|

12 |

316L、304L、304 alloy 625 825 2205 2507 |

φ4mm×1.1mm |

3000 |

500-2000 |

|

13 |

316L、304L、304 alloy 625 825 2205 2507 |

φ6mm×0.9mm |

2000 |

500-2000 |

|

14 |

316L、304L、304 alloy 625 825 2205 2507 |

φ6mm×1.1mm |

2000 |

500-2000 |

|

15 |

316L、304L、304 alloy 625 825 2205 2507 |

φ8mm×1mm |

1800 |

500-2000 |

|

16 |

316L、304L、304 alloy 625 825 2205 2507 |

φ8mm×1.2mm |

1800 |

500-2000 |

|

17 |

316L、304L、304 alloy 625 825 2205 2507 stainless steel coiled tubing |

φ10mm×1mm |

1500 |

500-2000 |

|

18 |

316L、304L、304 alloy 625 825 2205 2507 |

φ10mm×1.2mm |

1500 |

500-2000 |

|

19 |

316L、304L、304 alloy 625 825 2205 2507 |

φ10mm×2mm |

500 |

500-2000 |

|

20 |

316L、304L、304 alloy 625 825 2205 2507 |

φ12mm×1.5mm |

500 |

500-200 |